Ms. Jenny Wang

What can I do for you?

Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,CPT,EXW,FAS,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

Min. Order:1000 Set/Sets

Transportation:Ocean,Air,Express,Land

Port:Ningbo,Shanghai,Shenzhen

$10000≥1000Set/Sets

Model No.: CT-10490

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Plastic

Product: Household Product

Shaping Mode: Injection Mould

Surface Finish Process: Polishing

Mould Cavity: Single Cavity

Plastic Material: PE

Process Combination Type: Single-Process Mode

Application: Car

Runner: Hot Runner

Design Software: Pro-E

Certification: ISO

Standard: DME

Customized: Customized

Packaging: Wooden box

Productivity: 500000shots/mold life- 1000000

Transportation: Ocean,Air,Express,Land

Place of Origin: China

Supply Ability: 10sets/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,CPT,EXW,FAS,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

The front and rear bumpers of cars are made of plastic, known as plastic bumpers. The plastic bumper of a car is composed of outer plate, cushioning material and beam. The outer plate and cushioning material are made of plastic, the cross-beam is pressed with cold-rolled sheet to form U-shaped groove, and the outer plate and cushioning material are attached to the cross-beam.

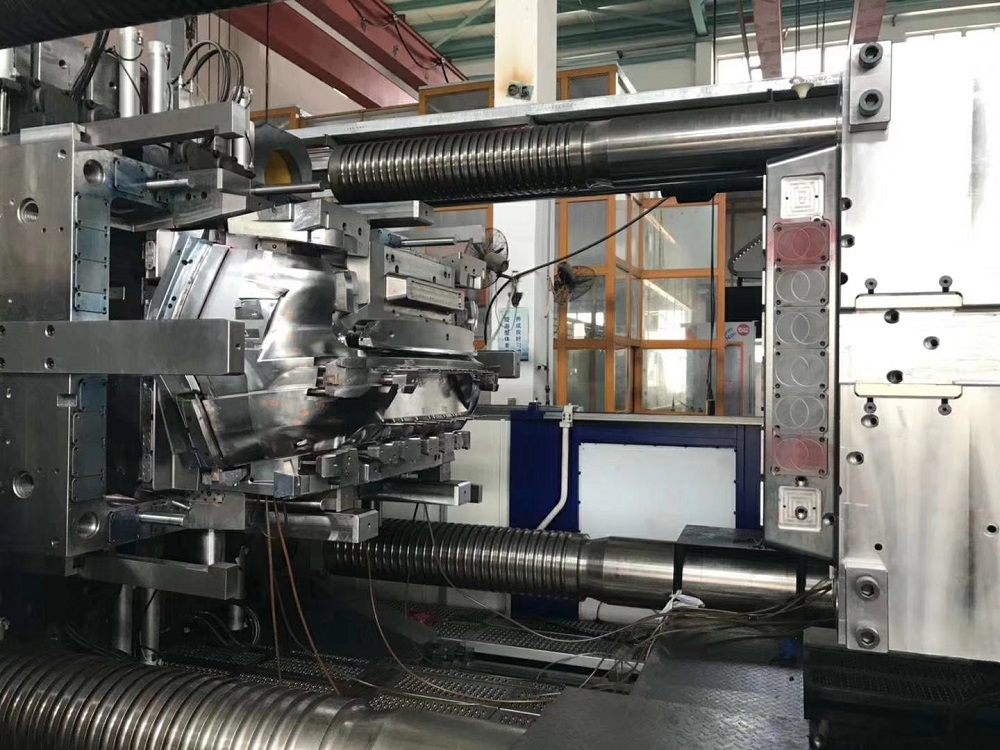

Technical information for Car front bumer and rear bumper mould

Ceeto Service Scope to manufacture car bumper mould

Plastic Car Front Bumper and rear bumper mould test

Before we ship bumper mould to you, we will have bumper mould buy-off in house together with you, and we must make official at least three mould tryouts and 2000 empty cycle for mould to check if mould function is ok in a certain time.

Normally, you and we attend the validation procedure together and sign off after checking. What we are checking usually are as follows:

Plastic car bumper mould material and heat treatment

What we will also inspect mould material and heart treatment as follows:

We warmly welcome you to visit us and send us RFQ, we want to be your part of suppliers and we will do our utmost efforts to make high quality of moulds and products, if you have any doubts about technical points, please don't hesitate to let us know, we are looking forward to hearing from you, thanks a lot.