Ms. Jenny Wang

What can I do for you?

Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,CPT,EXW,FAS,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

Min. Order:1 Set/Sets

Transportation:Ocean,Air,Land,Express

Port:Ningbo,Shanghai,Shenzhen

$1000-50000 /Set/Sets

Model No.: CT-1096

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Plastic

Product: Household Product

Shaping Mode: Injection Mould

Surface Finish Process: Polishing

Mould Cavity: Single Cavity

Plastic Material: HDPE

Process Combination Type: Single-Process Mode

Application: Home Use

Runner: Hot Runner

Design Software: UG

Installation: Fixed

Certification: ISO

Standard: DME

Customized: Customized

Packaging: Wooden box

Productivity: 300000shots/year to 100000 sho

Transportation: Ocean,Air,Land,Express

Place of Origin: China

Supply Ability: 50molds/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,CPT,EXW,FAS,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

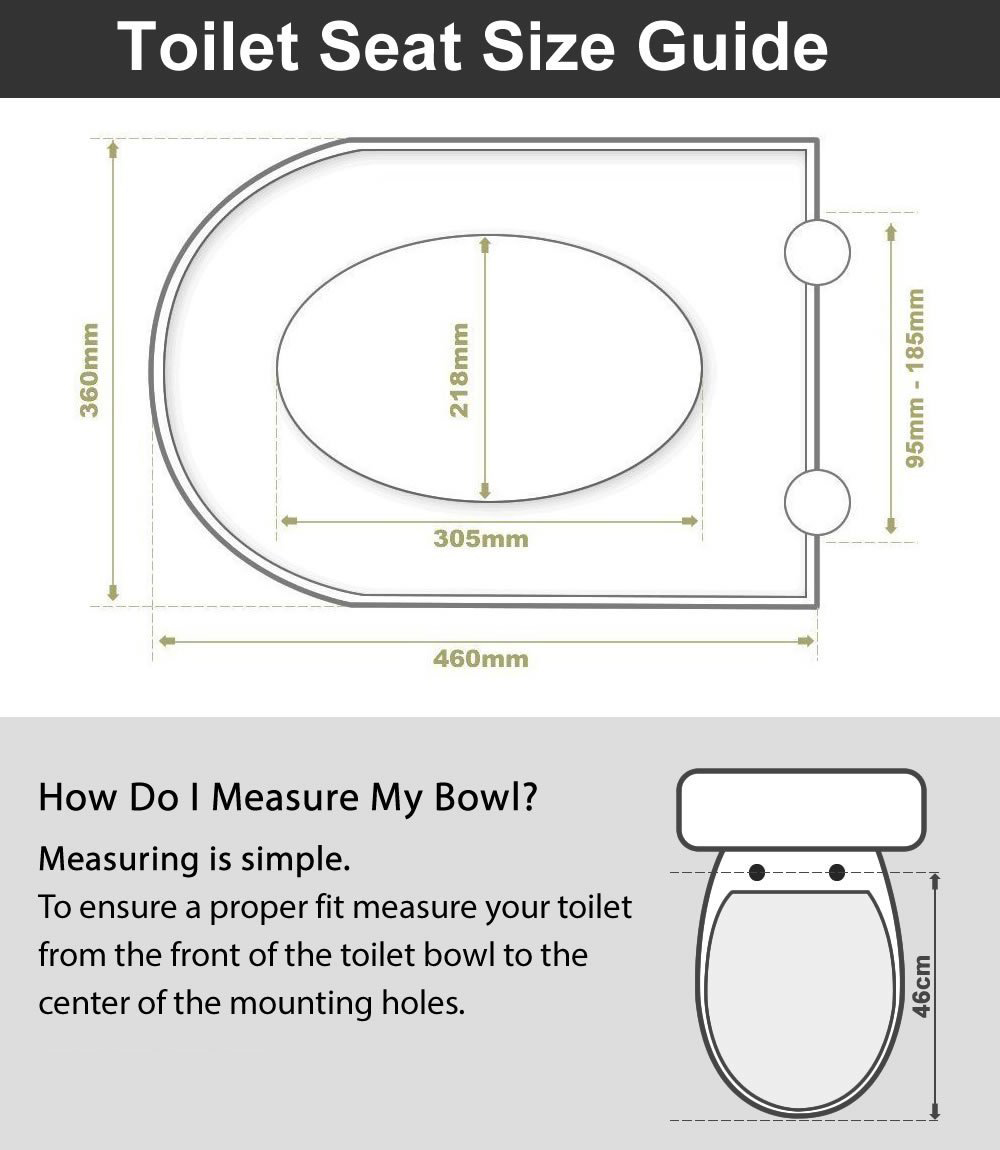

Frequently used plastic toilet seat pad cover injection mould is used to produce plastic toilet seat pad cover products, it's soft close D shaped toilet seat with Top fixing hinges, light weight- easy to fit, hygienic and easy to clean, ergonomic design for comfort, strong top fixing hinges, suitable for most toilets, and easy to install.

Ceet has many years in design and making plastic toilet seat pad cover injection mould and product injection, most of mould components are made in house.

Technical Specification on Plastic Toilet Seat Cover Mould

Workshop to make plastic toilet seat cover mould

Working procedures are as follows: we start DFM analysis and moldflow analysis when we receive your kick-off 2D drawing and 3D models with shrinkage rate and your injection machine technical specification. We submit the complete mould design including water line design and hot runner system design for your review and approval, certainly we will have design technical modifications back and forth during mould design stage, when you approve our mould design, and you will give us order to buy mould steel and give us approval to cut steel block, rough cutting is completely done when we get steel block from our steel supplier, what we will do is to machine cavity block and core block by high speed CNC milling from CNC equipment, Electrical Discharge Machining (EDM) and WEDM, Gun drilling machine is well used to drill mould water line hole, and any other general machining equipments.

You will definitely know our machining procedures through our Program Manager who is in charge of your plastic toilet seat cover mould machining process, he will report you the machining works weekly and he will submit you with weekly report reflecting timing chart, until we finish this plastic toilet seat cover mould and implement T0 which we call mould tryout in house, we will also send you the mould tryout report and plastic toilet seat cover samples to review.

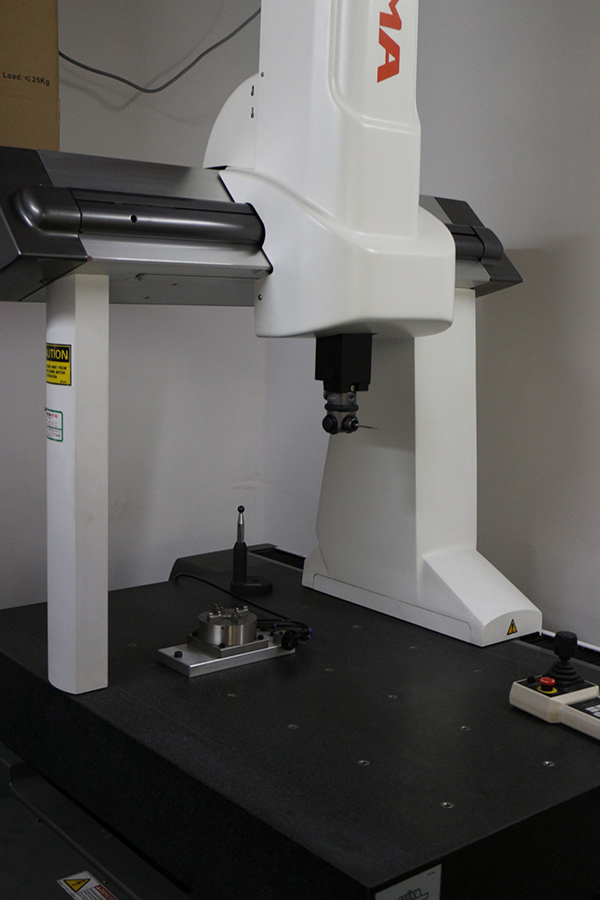

Quality Control to Plastic Toliet Seat Cover Mould

Our advantage if you order plastic toilet seat cover mould

Warmly welcome you to send us inquiry at your convenient time, we do wish you to contact us if you have any technical questions about plastic toilet seat cover mould or product, we will be very glad to give you response in 24 hours. Looking forward to hearing from you soon, thank you very much.