Ms. Jenny Wang

What can I do for you?

Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,FAS,EXW,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Min. Order:1 Set/Sets

Transportation:Ocean,Air,Land,Express

Port:Ningbo,Shanghai

$1000-50000 /Set/Sets

Model No.: CT-10508

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Plastic

Product: Household Product

Mould Standard Can Be HASCO,MISUMI.: Mould Design Can Be Pro-E As Well

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Air,Land,Express

Place of Origin: China

Supply Ability: 30sets/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,FAS,EXW,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Wall Mounted Plastic Power Socket Moulds can be designed multi- caviy injection, different wall power socket products will make your house or apartment look perfect, so product surface finishing need high polishing technical requirement, therefore, when we finish the mould, we must make good polishing on the mould in order to have very good outside surface.

Wall Mounted Plastic Power Socket Mould Technical Description

Our processing for making Wall Mounted Plastic Power Socket Mould

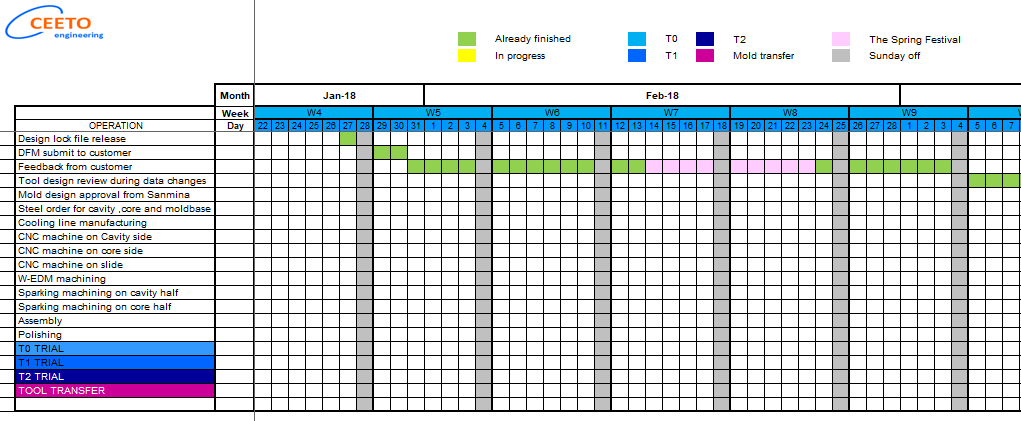

When we receive your official purchasing order, we will set up an internal meeting with mould designer, Project Manager, Production Manager, Project Manager will be in charge of the whole program since this design stage to mould shipment after mould inspection approval, and report to you mould design progress and machining processing progress with weekly report which means that he or she will report you very week about jobs that we do on this program, here is weekly report showing you dynamic timing chart:

Quality Control For Wall Mounted Plastic Power Socket Mould

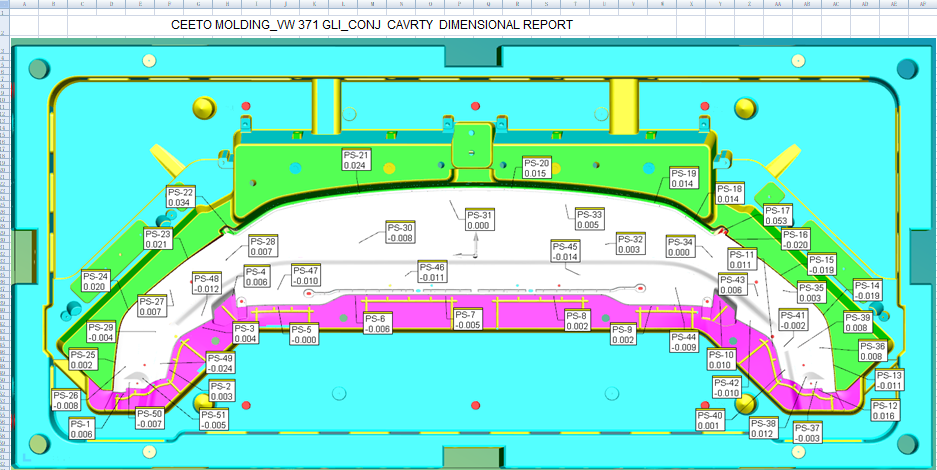

When we receive mould steel blocks, we ask for steel certification and steel inspection by ourselves, when we make the first mould tryout, we measure plastic sample parts using calipers and CMM measuring equipments, we also measure the critical dimensions on plastic fan blade injection moulds and analyze the reasons of all the "NG" points on measuring reports, we will share these reports with you and find solutions together with you to improve moulds. Here is example of measuring report for mould:

We warmly welcome you to send out an inquiry to us, we will give you mould cost in details with our professional working procedures and strict program management, if you have any technical questions, please don't hesitate to keep us informed, looking forward to hearing from you, thank you very much.