Ms. Jenny Wang

What can I do for you?

Payment Type:L/C,T/T,D/P,D/A

Incoterm:FOB,DDU,CFR,CIF,EXW,DAF,FAS,DES,FCA,CPT,CIP,DEQ,DDP

Min. Order:1000 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Ningbo,Shenzhen,Shanghai

$10000≥1000Piece/Pieces

Model No.: CT-2024313-02

Brand: CEETO

Place Of Origin: China

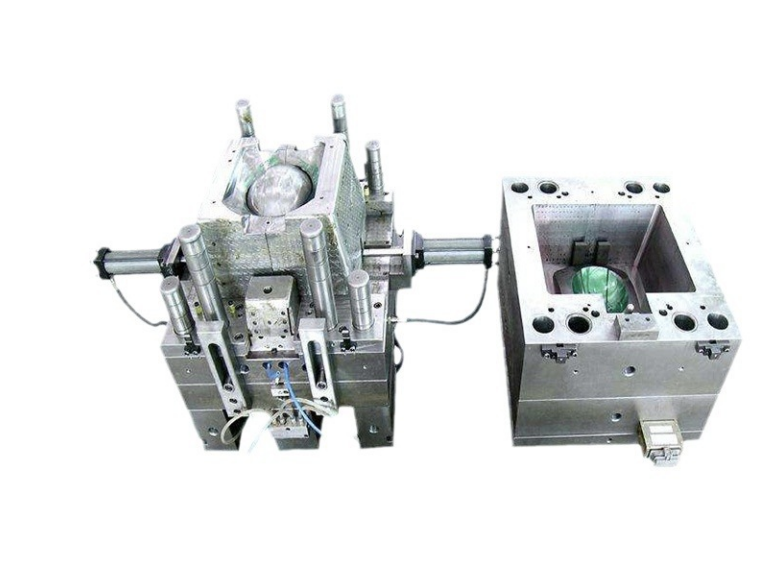

Forming Method: Plastic Injection Mould

Product Material: Plastic

2D Drawing And 3D Modls Available: Platsic resin can be PP,ABS,PET,TPE,PC,PC/ABS,PE,PCR-PP,PCR-PC etc.

Platsic Resin Can Be PP,ABS,PET: Mold steel can be 718,718H,P20,P20HH,2738,and soon

Mold Base:LKM: Standard components can be Punch,DME,HASCO.

Standard Components Can Be Punch,DME,HAS: Hot runner system can be synventive,Yudo etc.

Ejection System:Ejection Pins: Cooling lines:as per client's requirements.

Moldflow Analysis:included: 3D printing included if necessary

Support Prototype Molds: Support production molds

Production Mold Life:1500000 Shots: clamping force:as per mold design.

Wall Thickness As Per Product Design: Mold testing:3 official times

Cycle Times:25s: Mold packing:wooden box

Packaging: carton box with pallets

Productivity: 50molds/month

Transportation: Ocean,Land,Air,Express

Place of Origin: Ningbo,China

Supply Ability: 50pieces/month

Certificate: ISO9001

Port: Ningbo,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,D/A

Incoterm: FOB,DDU,CFR,CIF,EXW,DAF,FAS,DES,FCA,CPT,CIP,DEQ,DDP

Custom plastic injection molds for all kinds of plastic components for Aircraft industry, mainly such as air plane seat plastic components, armrest plastic part, back armchair, economy seats plastic parts components. With the development and demand of the civil aviation industry, the design of aircraft cabin seat structure is no longer limited to safety, comfort, beauty, durability and other practical functions.

The aircraft cabin seat armrest beam shell plastic injection mold comprises a lower backplane and an upper backplane. A fixed plate is installed on the lower backplane through two symmetrical support plates, a lower template is fixed on the fixed plate, a punch matching the shape of the inner cavity of the armrest beam shell to be processed is embedded on the lower template, and a T-shaped chute is symmetrically arranged on both sides of the punch at the right end of the punch. A slide block is inserted into a T-shaped chute.

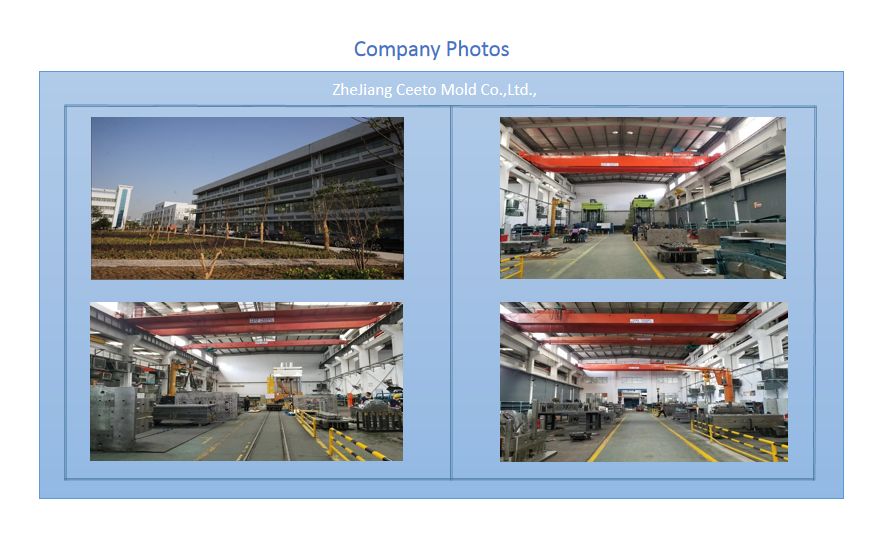

Zhejiang Ceeto Mold Co.,Ltd. has much experience in design and manufacturing this kind of plastic injection molds with advanced machining equipments.

Main processing equipment

Machining center linear cutting grinding machine Milling machine drilling machine

Number of processing equipment :20

Processing capacity :100000

Process type :Injection molding die

Number of die parting surfaces

Multiple parting surfaces :Number of cavity

Multi-cavity mold

Mold installation method

Mobile die

Scope of application

Food, daily necessities, mobile phones, Home Appliances, automobiles, instruments, electronics, tableware, medical, crafts

Quality System: iso9001

Arrangement mode :horizontal

Mold material :45 steel p20 718 718H 2738

…… FAQ ……

Q1: Do you send samples for customized products?

A: Yes, we,Zhejiang Ceeto Mold Co., Ltd. is mainly manufacturing customized stainless steel products. We welcome sample orders to test and check product quality.Mixed samples are also acceptable for us.

Q2: What about deep drawing dies development delivery time?

A: lt usually takes 25 days ~ 45 days stamping dies such as deep drawing dies according to different products, much more complicated products will take longer time for example approx.. 45 days.

Q3: Do you have a minimum order quantity limit?

A: The minimum order quantity is low, and 1pc sample is available for quality inspection

Q4: How do you deliver sample goods and how long does it take to arrive?

A: We usually deliver sample goods by DHL.UPS.FedEx or TNT. It usually takes 3-5 days to arrive Aviation and shipping are also optional.

Q5: How to purchase stainless steel products?

A: First. kindly share with us your technical request or application requirements such as sample or 2D drawings or 3D models. Secondly, we offer you a reasonable quotation in details according to your request. Customers confirm samples and place deposit for formal order.Then, we arrange production or stamping dies development.

Q6: Can my logo be printed on stainless steel products?

A: Yes. Please inform us before our production and confirm any logo design according to our samples.