Ms. Jenny Wang

What can I do for you?

Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Min. Order:1 Set/Sets

Transportation:Ocean,Air,Land,Express

Port:Ningbo,Shanghai,Shenzhen

$1000-50000 /Set/Sets

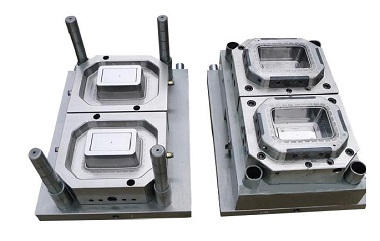

Model No.: CT-10106

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Plastic

Product: Household Product

Shaping Mode: Injection Mould

Surface Finish Process: Powder Coating

Mould Cavity: Single Cavity

Plastic Material: PE

Runner: Hot Runner

Design Software: UG

Installation: Fixed

Certification: ISO

Standard: HASCO

Customized: Customized

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Air,Land,Express

Place of Origin: China

Supply Ability: 20pcs/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

How to control quality?

Regarding quality control of plastic injection moulds, there are three steps:

1. Mould Material checking

- Mould Steel Checking (Hardness, flaw detection)

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2. Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- checking each part of mould's size after machining, according to 2D drawing

- mould testing(check mould running condition)

3. Check with customer's technical requirements once again before mould shipment

What can we guarantee: