Ms. Jenny Wang

What can I do for you?

Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Min. Order:1 Set/Sets

Transportation:Ocean,Air,Land,Express

Port:Ningbo,Shanghai,Shenzhen

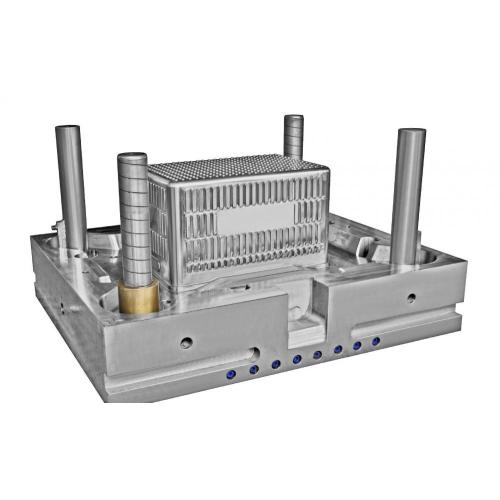

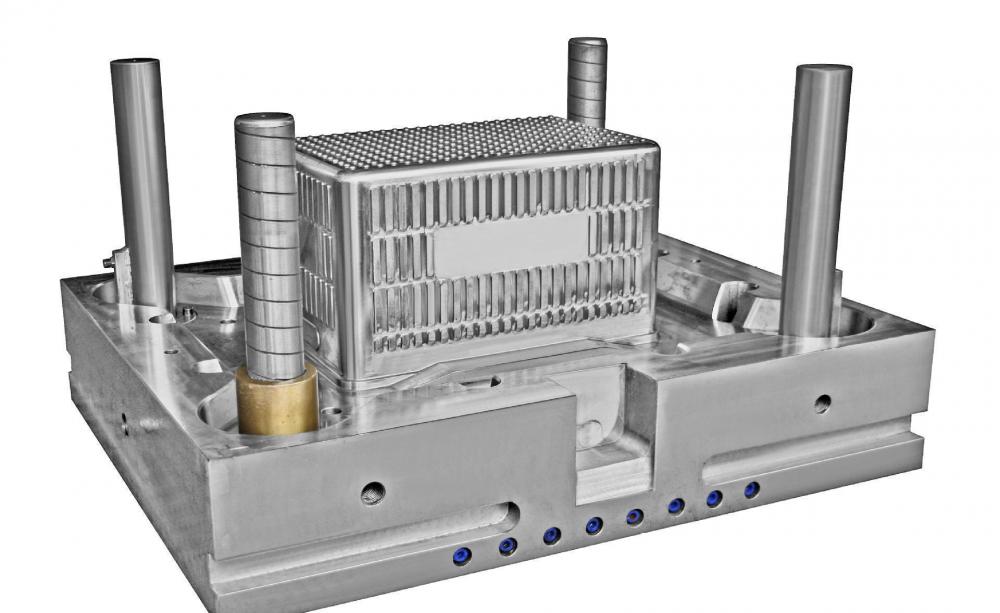

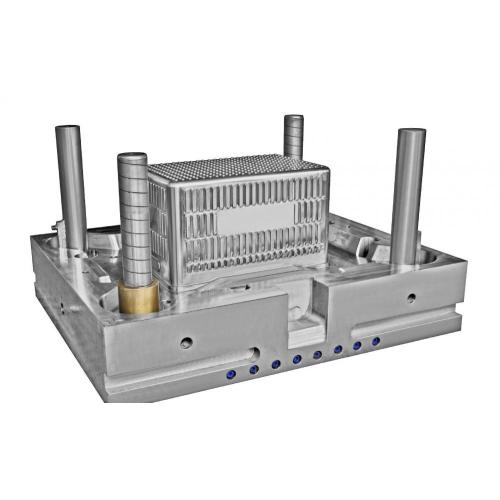

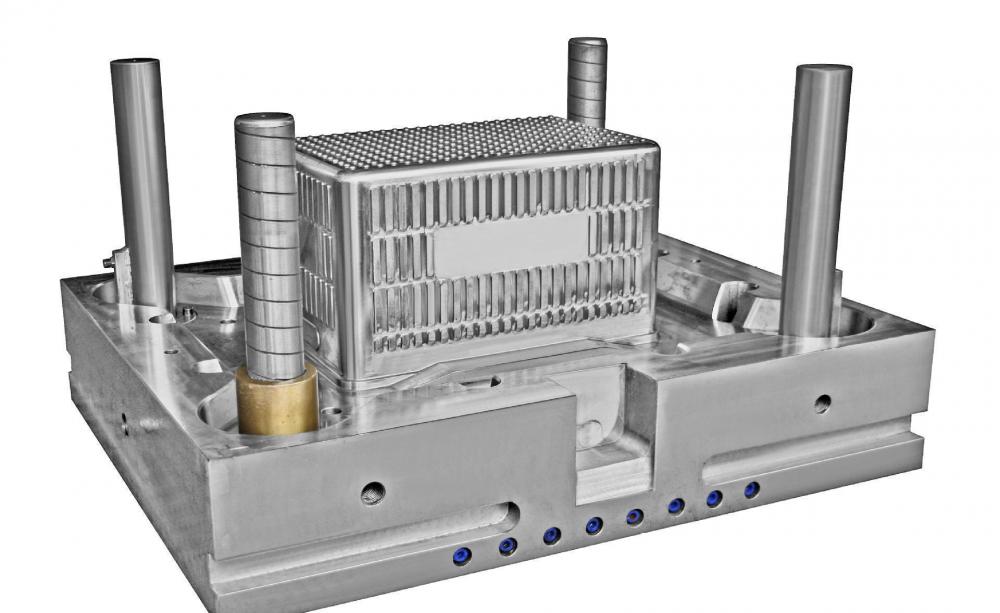

Model No.: CT11025

Brand: Ceeto

Forming Method: Plastic Injection Mould

Place Of Origin: China

Product Material: Plastic

Product: Household Product

Shaping Mode: Injection Mould

Surface Finish Process: Powder Coating

Mould Cavity: Single Cavity

Plastic Material: PE

Runner: Hot Runner

Design Software: UG

Installation: Fixed

Certification: ISO

Standard: HASCO

Customized: Customized

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Air,Land,Express

Place of Origin: China

Supply Ability: 10sets/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Ceeto Mold has been dedicated in design and manufacture plastic Crate Box mold and Plastic Fruit Box mold for many years, with rich experience, we have made all kinds of plastic crate box and plastic fruit box according to customer's technical requirements and we also could provide you with 3D model with your sample and make any changes in product design. Based on our technical experience, here we summarize how to design plastic fruit box parts and molds as follows.

⑴ The shape and wall thickness design of the plastic parts should be particularly considered to facilitate the smooth flow of the filling cavity and avoid sharp corners and gaps.

⑵ The release angle should be large, 15% with glass fiber can be 1 ° ~ 2 °, 30% with glass fiber can be 2 ° ~ 3 ° When the draft angle is not allowed, forcible demoulding should be avoided, and the horizontal parting structure should be adopted.

⑶ The cross-section of the pouring system should be large, and the process should be straight and short to facilitate the even dispersion of the fibers.

⑷The design of the feed inlet should consider the prevention of insufficient filling, anisotropic deformation, uneven distribution of glass fibers, and easy to produce weld marks and other adverse consequences. The feed port should be thin, wide, fan-shaped, ring-shaped and multi-point feed ports to make the flow turbulent and the glass fibers evenly dispersed to reduce anisotropy. It is best not to use needle-shaped feed ports. The mouth section can be increased appropriately, and its length should be short.

⑸The mold core and cavity should have sufficient rigidity and strength.

⑹The mold should be hardened, polished, and wear-resistant steel should be selected, and the parts that are easy to wear should be easy to repair.

⑺Ejection should be even and strong, convenient for replacement.

⑻The mold should be equipped with exhaust overflow trough, and should be set at the place where welding marks easily occur.

…… FAQ ……

Q1: Do you send samples for customized products?

A: Yes, we,Zhejiang Ceeto Mold Co., Ltd. is mainly manufacturing customized stainless steel products. We welcome sample orders to test and check product quality.Mixed samples are also acceptable for us.

Q2: What about deep drawing dies development delivery time?

A: lt usually takes 25 days ~ 45 days stamping dies such as deep drawing dies according to different products, much more complicated products will take longer time for example approx.. 45 days.

Q3: Do you have a minimum order quantity limit?

A: The minimum order quantity is low, and 1pc sample is available for quality inspection

Q4: How do you deliver sample goods and how long does it take to arrive?

A: We usually deliver sample goods by DHL.UPS.FedEx or TNT. It usually takes 3-5 days to arrive Aviation and shipping are also optional.

Q5: How to purchase stainless steel products?

A: First. kindly share with us your technical request or application requirements such as sample or 2D drawings or 3D models. Secondly, we offer you a reasonable quotation in details according to your request. Customers confirm samples and place deposit for formal order.Then, we arrange production or stamping dies development.

Q6: Can my logo be printed on stainless steel products?

A: Yes. Please inform us before our production and confirm any logo design according to our samples.