Ms. Jenny Wang

What can I do for you?

Payment Type:T/T,L/C,D/P,D/A,Paypal

Incoterm:FOB,DDU,CFR,CIF,EXW,DAF,FAS,DES,FCA,CPT,CIP,DEQ,DDP

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Shanghai,Ningbo,Shenzhen

$5000-25000 /Piece/Pieces

Model No.: CT-2024316-05

Brand: CEETO

Place Of Origin: China

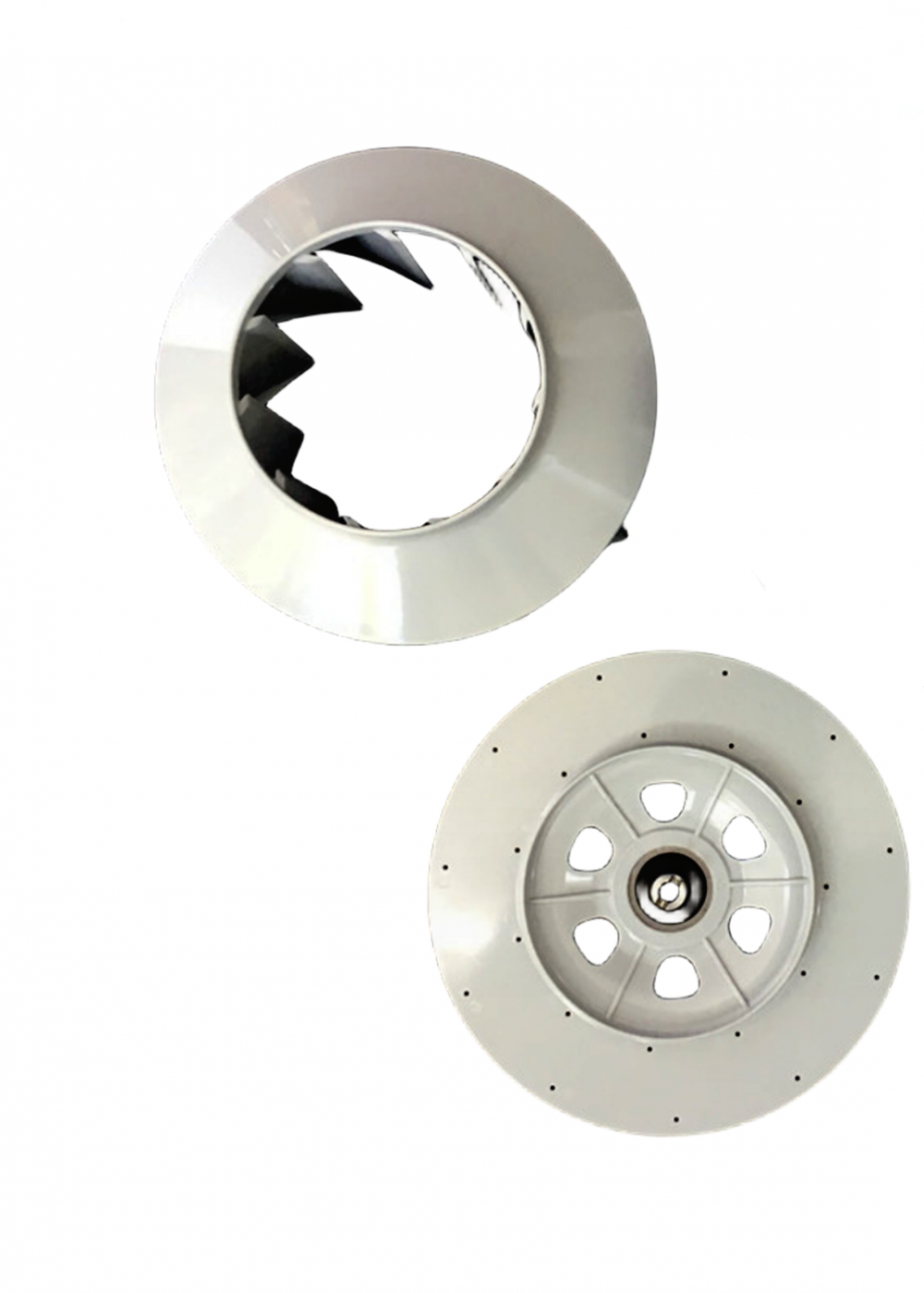

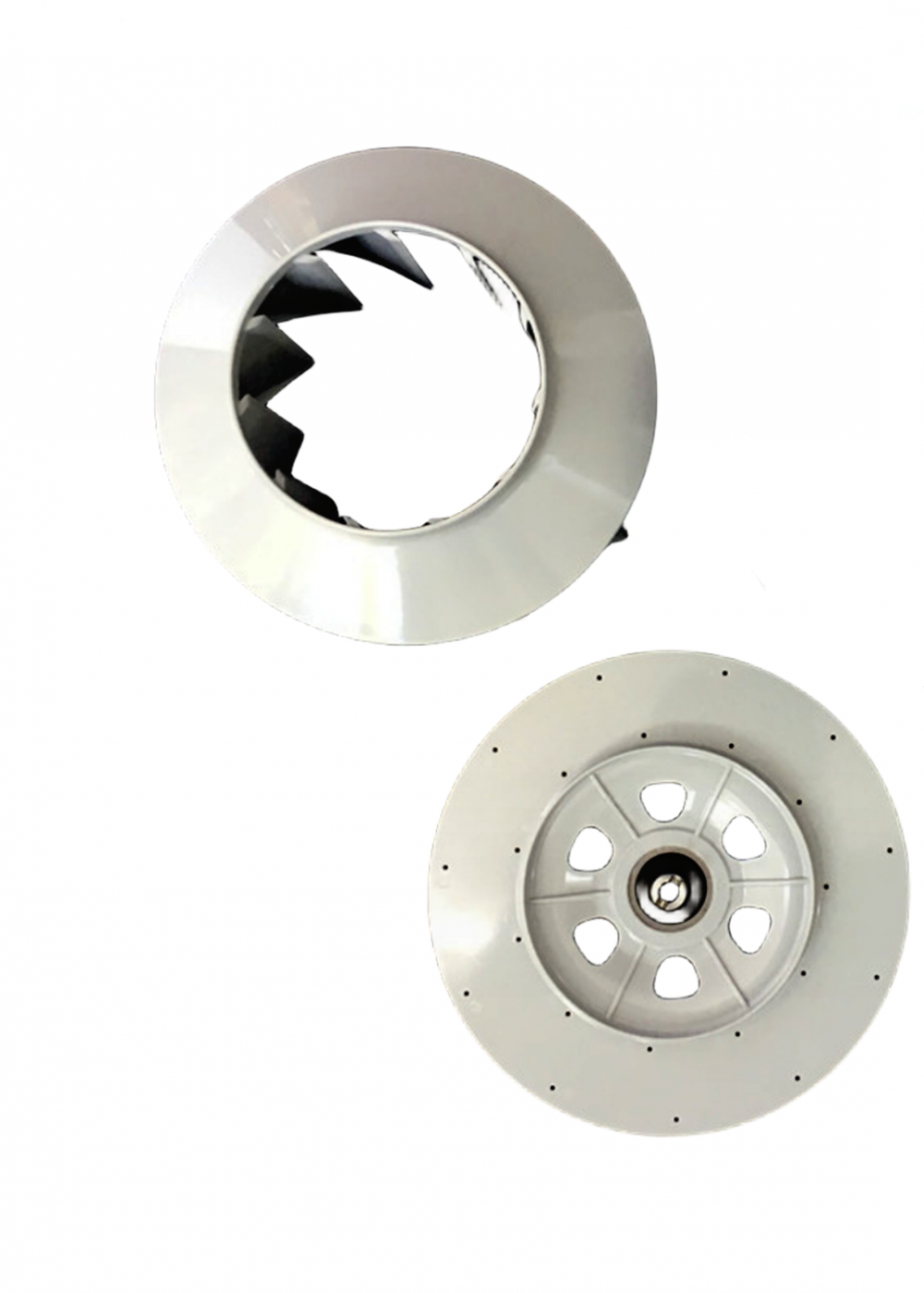

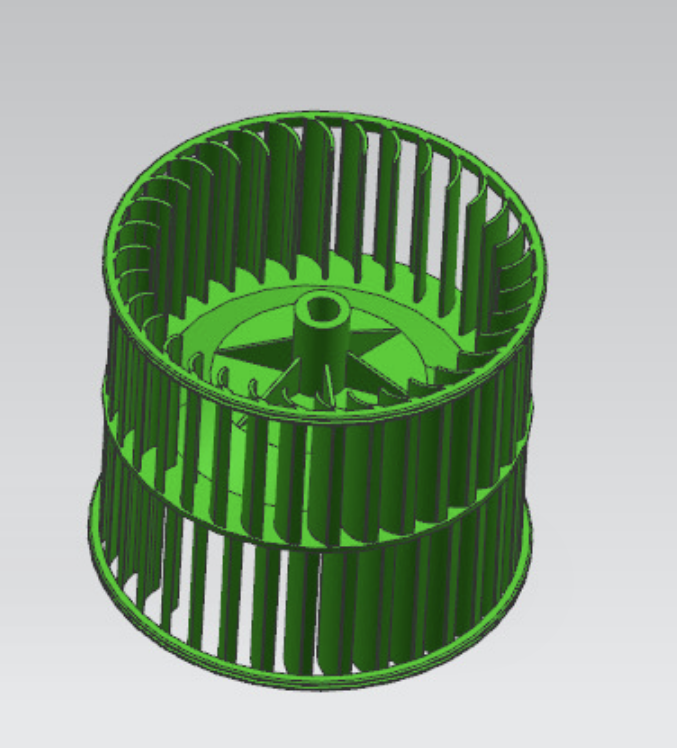

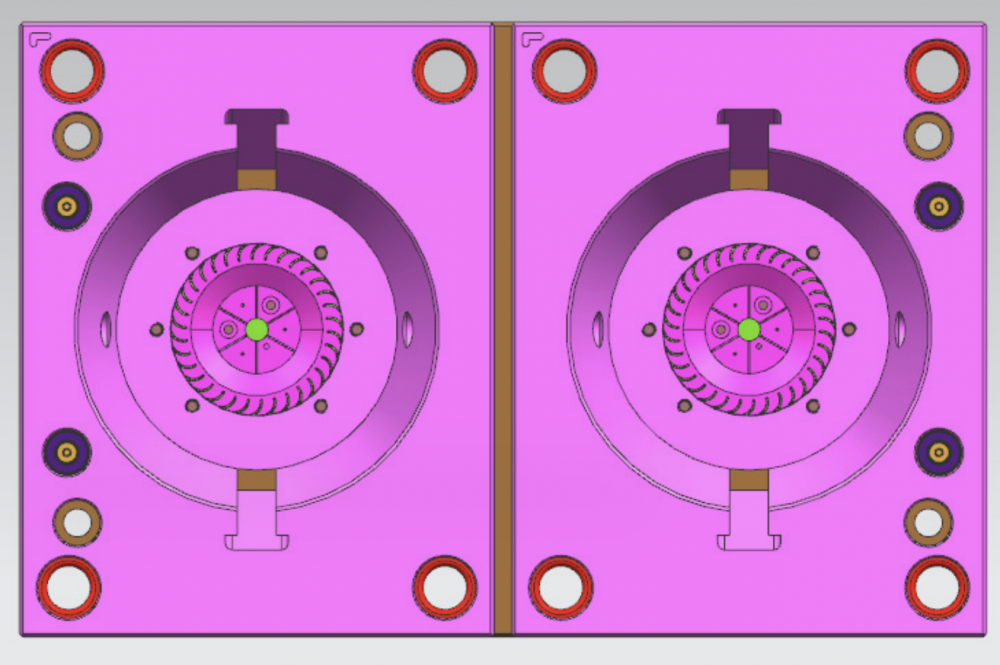

Forming Method: Plastic Injection Mould

Product Material: Plastic

2D Drawing And 3D Modls Available: Platsic resin can be PP,ABS,PET,TPE,PC,PC/ABS,PE,PCR-PP,PCR-PC etc.

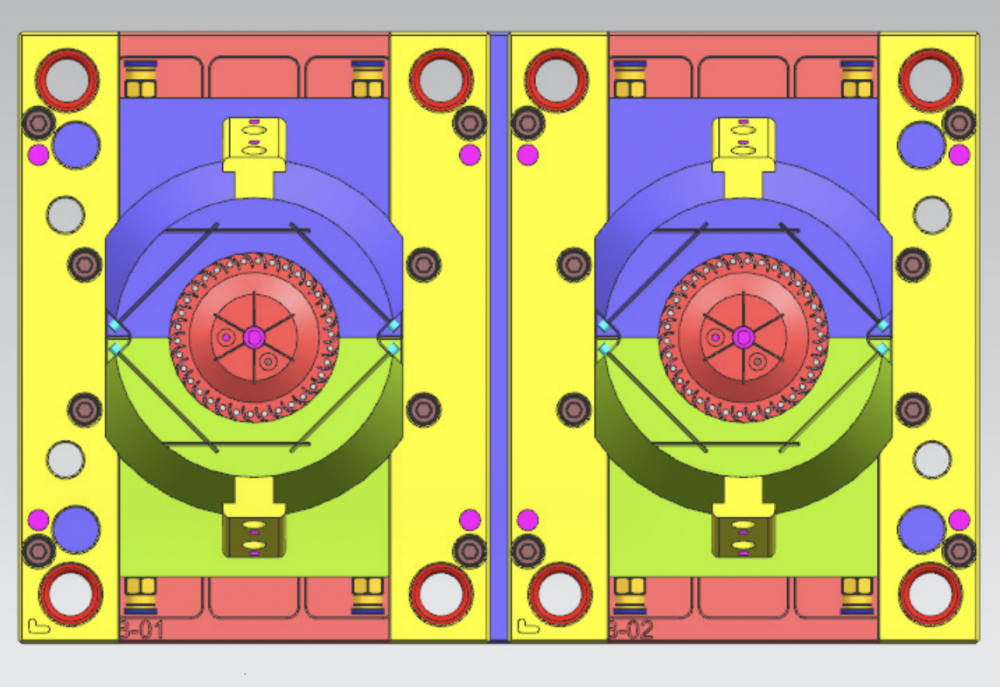

Mold Cavity Can Be 1 Or Multiple Cavity: Mold steel can be 718,718H,P20,P20HH,2738,and soon

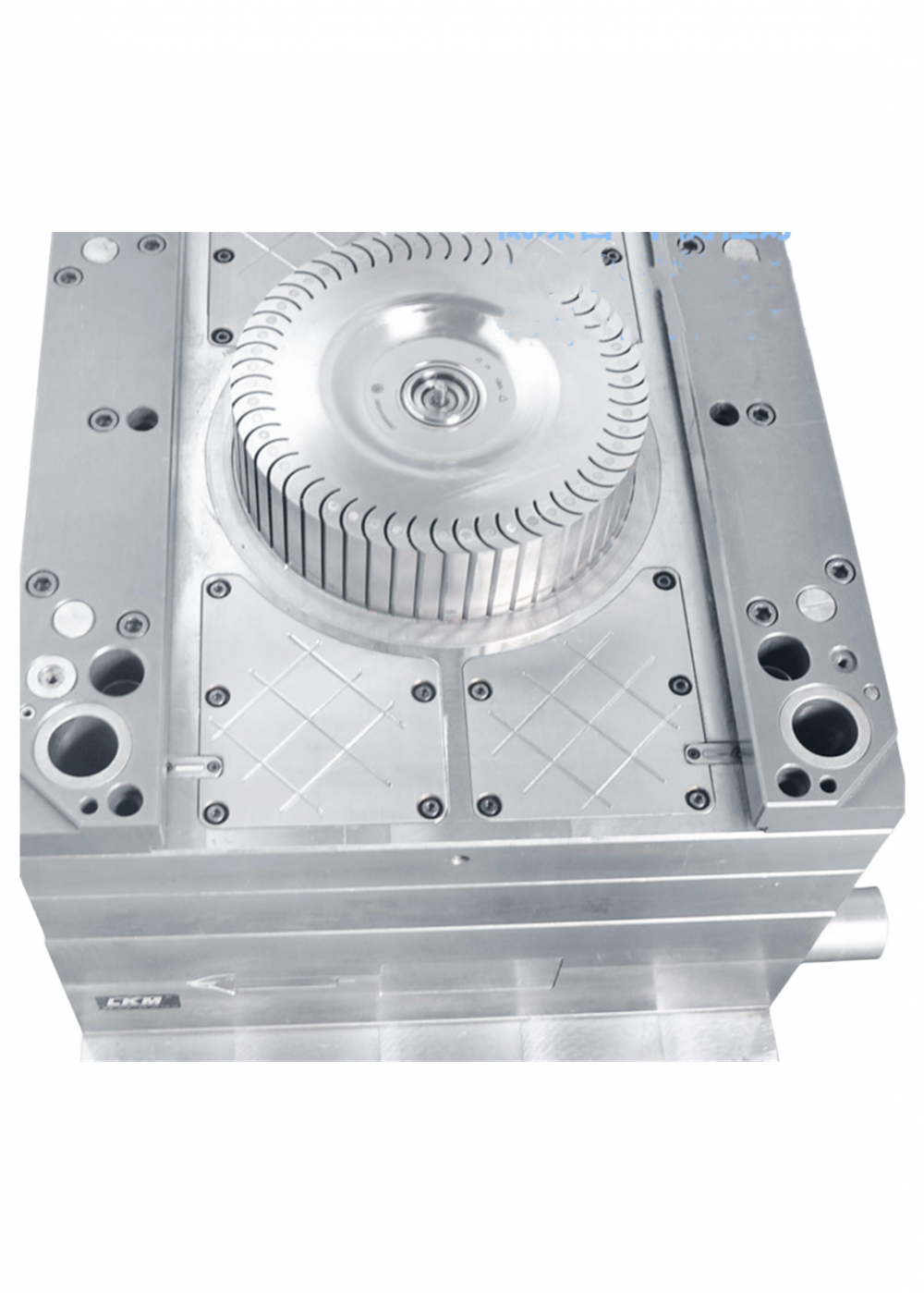

Mold Base:LKM: Standard components can be Punch,DME,HASCO.

Type Of Gate:cold Runner: Hot runner system can be Synventive, Yudo, Moldmaster

Ejection System:Ejection Pins: Cooling lines:as per client's requirements.

Moldflow Analysis:included: 3D printing included if necessary

Support Prototype Molds: Support production molds

Production Mold Life:1500000 Shots: clamping force:as per mold design.

Wall Thickness As Per Product Design: Mold testing:3 official times

Cycle Times:25s: Mold packing:wooden box

Packaging: Carton + wooden base

Productivity: 50 molds/year

Transportation: Ocean,Land,Air,Express

Place of Origin: Ningbo China

Supply Ability: 50 sets/month

Certificate: ISO9001

Port: Shanghai,Ningbo,Shenzhen

Payment Type: T/T,L/C,D/P,D/A,Paypal

Incoterm: FOB,DDU,CFR,CIF,EXW,DAF,FAS,DES,FCA,CPT,CIP,DEQ,DDP

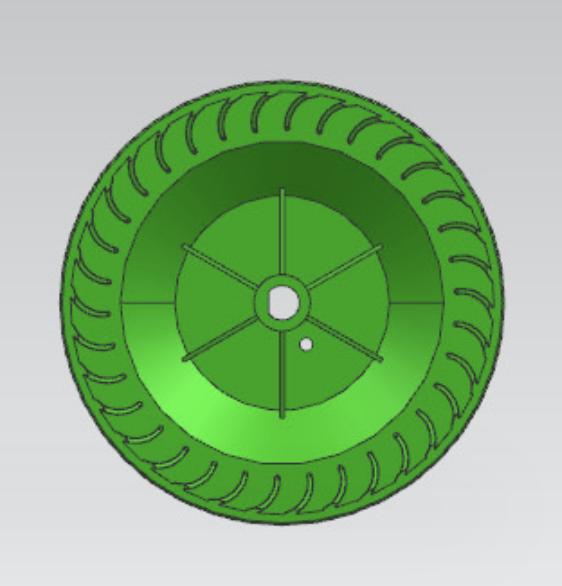

Generally, it is more scientific to set at least three or more sections of injection in molding of centrifugal Fans, that is, the first section at the main channel, the second section at the diversion channel to the gate, about 90% of the product filled cavity is the third section, and the remaining part is the fourth section, and the switching position of each section can be determined by calculating the weight method;

In actual production, the multi-stage injection process parameters should be scientifically analyzed and reasonably set according to the quality requirements of the plastic shell, the flow path structure and the exhaust status of the plastic mold.

Usually can be set by debugging observation method, set the pressure/speed required to find the switch position point during injection to 0, observe the direction of the hot melt adhesive and product defect status, and gradually adjust until a reasonable position point is found. However, in the process of debugging and observation, attention must be paid to the demoulding condition of the underinjection plastic shell, so as to avoid sticking mold in some depressed parts of the plastic mold due to underinjection.

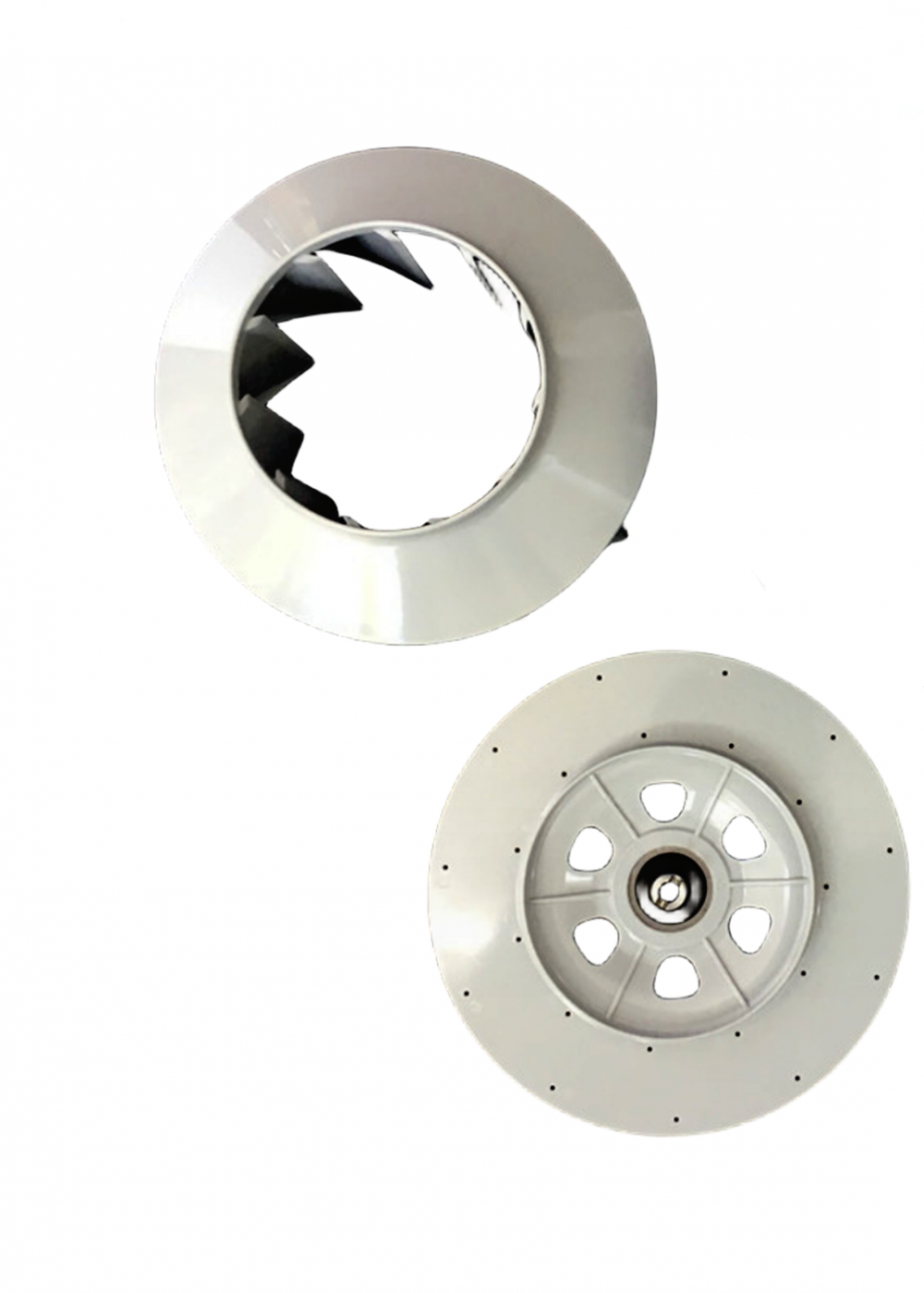

The plastic centrifugal Fans housing reaches the specified tension standard; The surface is free of all kinds of undesirable phenomena such as silver wire, bubbles, shrinkage marks; After forming, the plastic shell has good tightness and no loose phenomenon. The material used is PA66, the plastic mold structure is hot runner type, and the gate type is point gate.

Product description Plastic draught fan is a one kind of mechanical device which mainly has function is to generate wind power through rotation for applications such as ventilation, heat dissipation, or power generation. Zhejiang Ceeo Mold Co.,Ltd. is mainly providing you with high level plastic injection molds for all kinds of plastic components of draught fan device. Whateve any kinds of fan such as centrifugal fan, air blower, fax box and so on, we support molds development as per your design, what we can provide you with the following professional services: 1- 3D Printing 2- Prototype Mold Design and Manufacturing 3- Production Mold Design and Manufacturing 4- Moldflow analysis 5- CNC milling service 6- Mold design service