Ms. Jenny Wang

What can I do for you?

Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

Min. Order:1 Piece/Pieces

Transportation:Ocean,Air,Land,Express

Port:Ningbo,Shanghai,Shenzhen

$1000≥1Piece/Pieces

Model No.: CT- 20230321-05

Brand: CEETO

Place Of Origin: China

Forming Method: Preform Mould

Product Material: Plastic

Material: Polyethylene

Tank Thickness: 8mm

Working Medium: water

Working Pressure: atmosperic

Molding Method: Rotational moulding

Customization: Support customization

Mold Steel: Mold steel carbon steel

Mold Size: As per product design

Voume: 30m3 but can be customization

Field: Industrial

Packaging: oppo bags

Productivity: 50PCS/MONTH

Transportation: Ocean,Air,Land,Express

Place of Origin: China

Supply Ability: 30pcs/month

Certificate: ISO9001

HS Code: 3926909090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

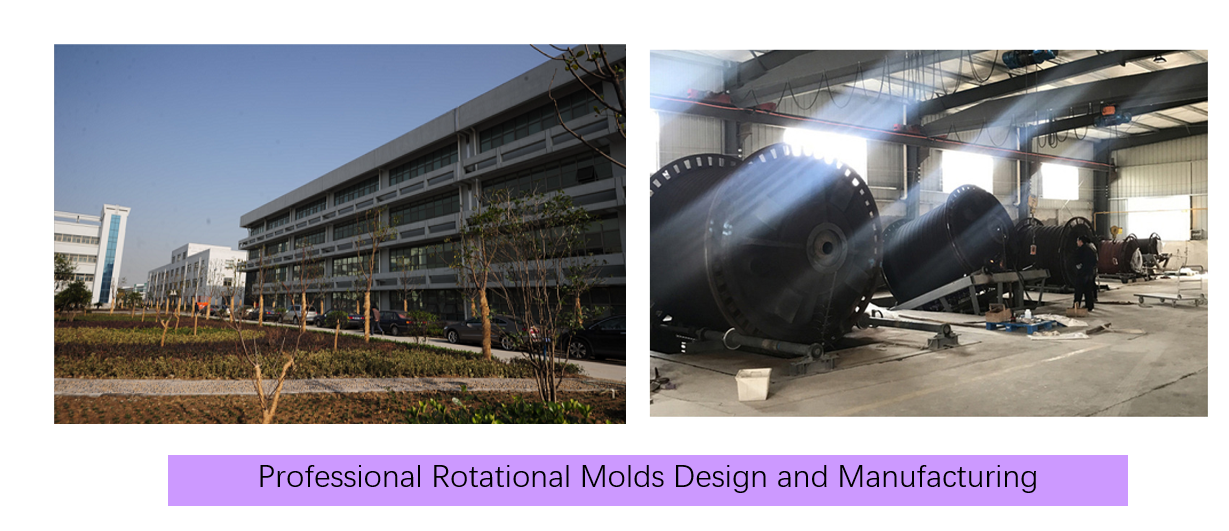

rotational molding is ideal for creating large, hollow parts with complex shapes, such as tanks, containers, and playground equipment. It is a cost-effective and efficient manufacturing process that can produce high-quality parts with consistent wall thickness and strength. Zhejiang Ceeto Mold Co., Ltd. is professtional to make high quality Rotational molds refers to many different kinds of tanks and containers.

Rotational molding, also known as rotomolding in many storage industries, is a manufacturing process used to create hollow plastic products. It involves the following steps:

1. Loading rotational mold: The mold is loaded with the desired amount of plastic resin in the form of pellets or powder.

2. Heating rotational mold: The mold is heated to a temperature that is high enough to melt the plastic resin inside.

3. Rotating rotational mold: The mold is rotated in two perpendicular axes simultaneously. This causes the molten plastic to coat the inner surface of the mold evenly.

4. Cooling the mold: The mold is cooled to a temperature that is low enough to solidify the plastic. This is typically done by circulating cool air or water through the mold.

5. Opening the mold: Once the plastic has solidified, the mold is opened, and the finished part is removed.

Rotational Molding is a manufacturing process that involves heating plastic material in a mold and rotating it slowly around two perpendicular axes. This process is commonly used to produce large, hollow objects such as tanks, containers, and playground equipment.

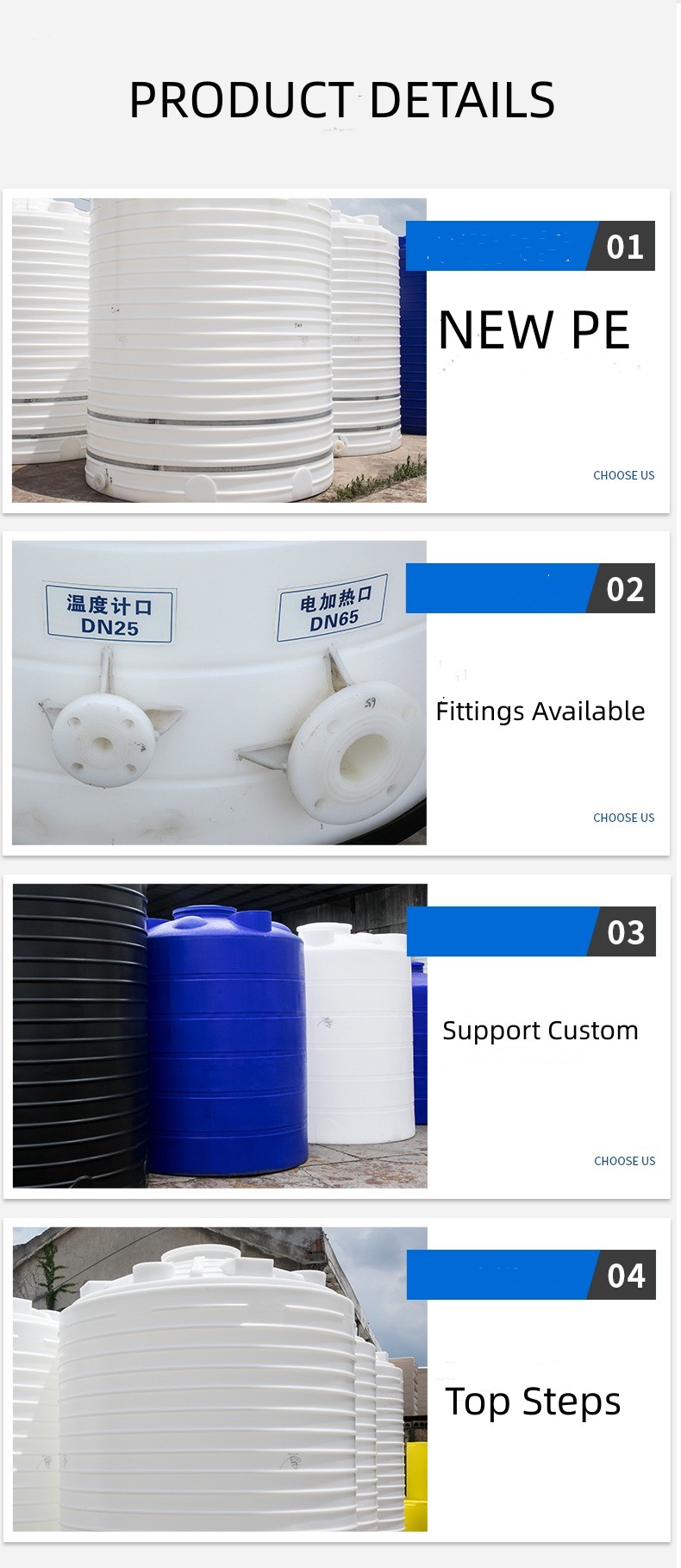

A rotational molding PE tank is a tank made using this process with polyethylene (PE) as the material. PE is a thermoplastic polymer that is lightweight, durable, and resistant to chemicals, making it an ideal material for tanks used in various industries such as agriculture, chemical processing, and water treatment.

The rotational molding process allows for the production of tanks with complex shapes and sizes, including those with multiple compartments, baffles, and fittings. Additionally, the process ensures that the tank has a uniform wall thickness, which provides strength and durability.

Overall, rotational molding PE tanks are a cost-effective and reliable solution for storing and transporting liquids and chemicals.