Plastic car exterior parts refer to front and rear bumper moulds, fog lamp moulds, and grilles and all plastic accessories, are requesting high quality with hardened steel 1.2738 or Finkl P20 hard steel in order to guarantee specified mould life such as 1000000shots. Plastic injection material is PP or ABS as per customer's requirement. Ceeto company has skilled design engineering team who is able to design plastic car bumper moulds as per part geometry, bumper mould design will be first considered hidden parting line or visible parting line according to DFM analysis and moldflow report.

Technical information for Car front bumper and rear bumper mould

- Design software: Pro-E

- Mould cavity: single cavity

- Molding material: PP, ABS, PE

- Mould cavity and core steel: 1.2738, P20, P20HH, 718H

- Hot runner system: Synventive, Yudo, HRS, Moldmaster

- Ejection system: Ejector pins, angle lifters

- Leadtime: 120 days

- Mould life: 500000 shots to 1000000 shots

- Mould packing: wooden box

Ceeto Service Scope to manufacture car bumper mould

- Plastic bumper product DFM analysis

- Moldflow analysis

- Plastic car bumper mould design

- Plastic car bumper mould assembly drawing

- Plastic car bumper mould machining

- Plastic car bumper mould testing via injection molding machine

- Plastic car bumper mould packing

- Plastic car bumper samples packing

- Mould spare parts preparation

- We also support you for prototype mould design and manufacture

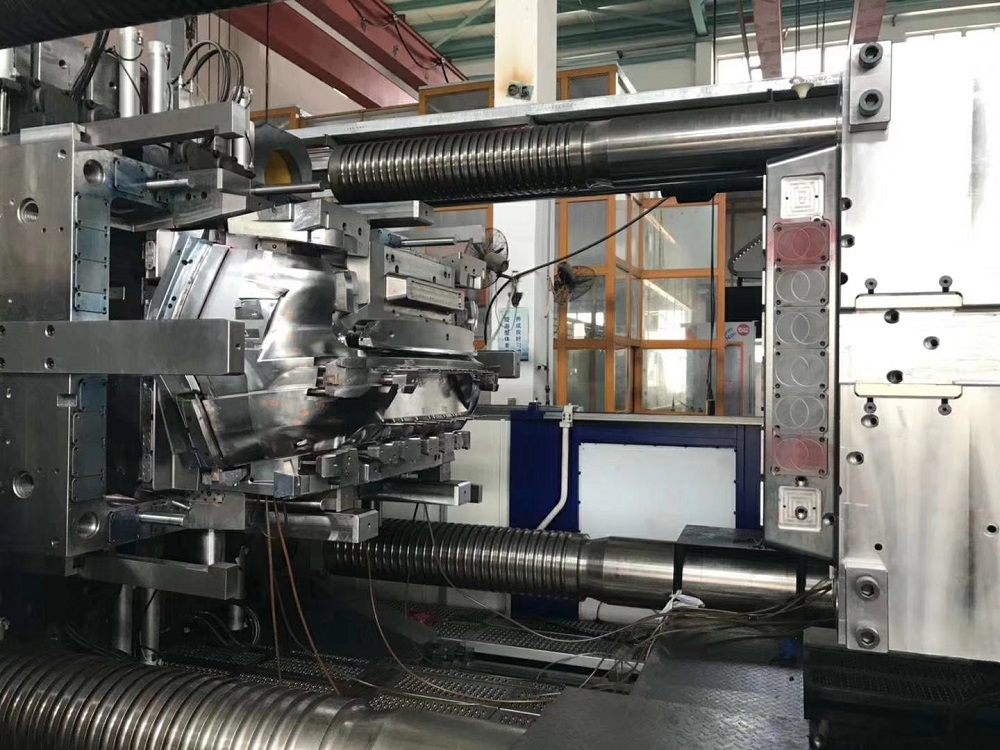

Plastic Car Front Bumper and rear bumper mould test

Before we ship bumper mould to you, we will have bumper mould buy-off in house together with you, and we must make official at least three mould tryouts and 2000 empty cycle for mould to check if mould function is ok in a certain time.

Normally, you and we attend the validation procedure together and sign off after checking. What we are checking usually are as follows:

- Compatibility with Injection Machine to be used

- Is size of the mould ( Leight* width* Height ) correct?

- Is weight of the mould is correct?

- Are lifting eyebolts fully seated on the mold and not interfering with mold action?

- Are all transportation bars installed and in correct color as you request?

- Are knock-out holes for mechanical ejection and the layout correct as designed?

- Is electric box wired correctly as per injection machine standard?

- Are dimensions of locating ring correct?

- Is radius and orifice diameter of sprue bush correct?

- Are clamping features correct?

- Is the mold construction compatible with robot gripping if applicable to take off part?

Plastic car bumper mould material and heat treatment

What we will also inspect mould material and heart treatment as follows:

- Is any welding used on mold? Is welding process correct for the steel used?

- Have all mold plates been stamped with markings?

- Provide the heat treatment certificate and hardness for all applicable mold components

- Are moving parts nitrided? Provide nitride certificate.

We warmly welcome you to visit us and send us RFQ, we want to be your part of suppliers and we will do our utmost efforts to make high quality of moulds and products, if you have any doubts about technical points, please don't hesitate to let us know, we are looking forward to hearing from you, thanks a lot.