Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Ms. Jenny Wang

What can I do for you?

![]() January 15, 2024

January 15, 2024

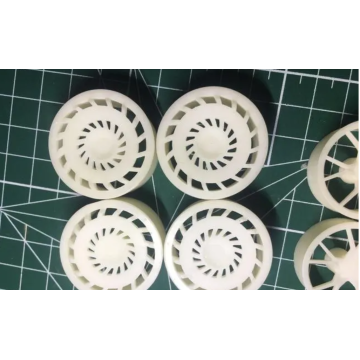

New plastic products or plastic sample parts are normally produced by plastic injection molds. Injection molds are usually made of a specified steel metal with good thermal conductivity. In addition to steel such as H13 or P20 metal molds, 3D printed plastic technology is normally used by most of companies now to produce plastic prototype products instead of making prototype molds at beginning.

Under what circumstances do you use 3D printed plastic parts? Compared with plastic injection molds, what are the issues that need to be paid attention to in 3D printing plastic molds? In order to save time and cost against making a new prototype molds.

Bosch Rexroth, Airbus, Porsche and other companies in the new product development, often need to make small batches of injection products within a few days, and functional testing. As a prototype manufacturer serving these three companies, Wehl & Partner's primary task after receiving customer orders is to quickly manufacture molds for the production of these injection molded products.

DSM

Wehl & Partner uses SLA (stereo-curing) 3D printing technology to quickly manufacture injection molds using the DSM Somos Perform resin. This material has a good surface finish. If machining is used to make a metal mold, and then using a mold for product injection, it takes 5-7 weeks. With 3D printing molds, injection molded products can be delivered to customers in just 1-2 weeks. The printing material used by Wehl & Partner is a liquid resin material with good heat resistance that can withstand temperatures up to 120 degrees Celsius. The temperature of the mold does not affect the strength and precision of the material during injection molding.

If the material used for injection molding is polypropylene, Wehl & Partner prints plastic molds that can produce hundreds of products. If you are using fiberglass materials, you can produce about 40-50 products per mold.

Metal or plastic?

Is it a metal mold or a plastic mold? Wehl & Partner has explored its own answers through practice. Metal molds and 3D printing injection molds made using traditional processing methods are used by Wehl & Partner when they serve customers. When customers need to produce hundreds or thousands of injection molded products, they use aluminum molds to produce them.

Mold insert

If the customer's product design is relatively simple, Wehl & Partner still uses mechanical machining to make metal injection molds. 3D printed plastic molds will be the first choice for Wehl & Partner when product design is complex or when customer deadlines are tight.

SLA is not the only 3D printing technology used to print plastic injection molds. Material injection technology also has this application. For example, Stratasys' Polyject material jet 3D printer can also be used to make injection molds by printing ABS digital materials. Whale, a supplier of heating systems, uses this technology to print injection molds and use them to produce prototypes of new products in small batches. The use of this technology for small batch production in new product development has reduced lead times by 97%.

Mold manufacturer HASCO uses this technology to print complex mold cavity parts, such as inserts, in mass production molds. If the insert of the mold needs to be modified, a faster design modification can be achieved than with conventional mold manufacturing methods. Fast mold change with 3D printed cavities is a fast and economical alternative to traditional methods.

Despite the 3D printed plastic injection mold, it saves time and cost compared to manufacturing metal molds. However, in the injection molding process, the liquid injection molding material has a high temperature, and the quality of the plastic product can be ensured only by uniformly and rapidly cooling after the injection molding. This requires the mold to have good thermal conductivity, and it is not difficult to imagine that the thermal conductivity of plastic cannot be compared with metal. The thermal conductivity of the plastic mold is weak, and the cycle of injection molding becomes long. 3D printed plastic molds are more suitable for the production of small quantities of new products in the development stage, or a small number of urgent products, as well as small and medium-sized injection products.

The above is the Making plastic prototype molds with plastic? 3D printing is cost saving! we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.